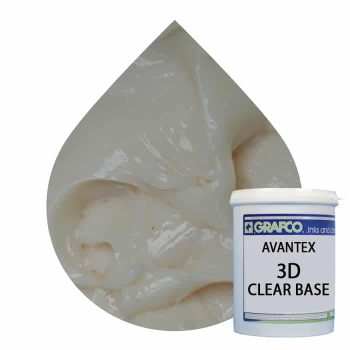

PLASTISOL INK AVANTEX

16,14 € – 180,70 € + VAT

Plastisol AVANTEX ink for direct screen printing on textiles and for printing transfers with a matte effect.

1 kg

5 kg

18,38 € + VAT

83,93 € + VAT

39,66 € + VAT

180,70 € + VAT

25,73 € + VAT

119,63 € + VAT

16,14 € + VAT

67,13 € + VAT

31,89 € + VAT

150,75 € + VAT

27,00 € + VAT

126,38 € + VAT

34,91 € + VAT

159,83 € + VAT

33,80 € + VAT

159,83 € + VAT

30,75 € + VAT

153,75 € + VAT

32,93 € + VAT

156,00 € + VAT

32,93 € + VAT

144,08 € + VAT

27,27 € + VAT

116,10 € + VAT

23,93 € + VAT

110,63 € + VAT